Tel: +44(0) 1246 292292 | alloys@wbrl.co.uk

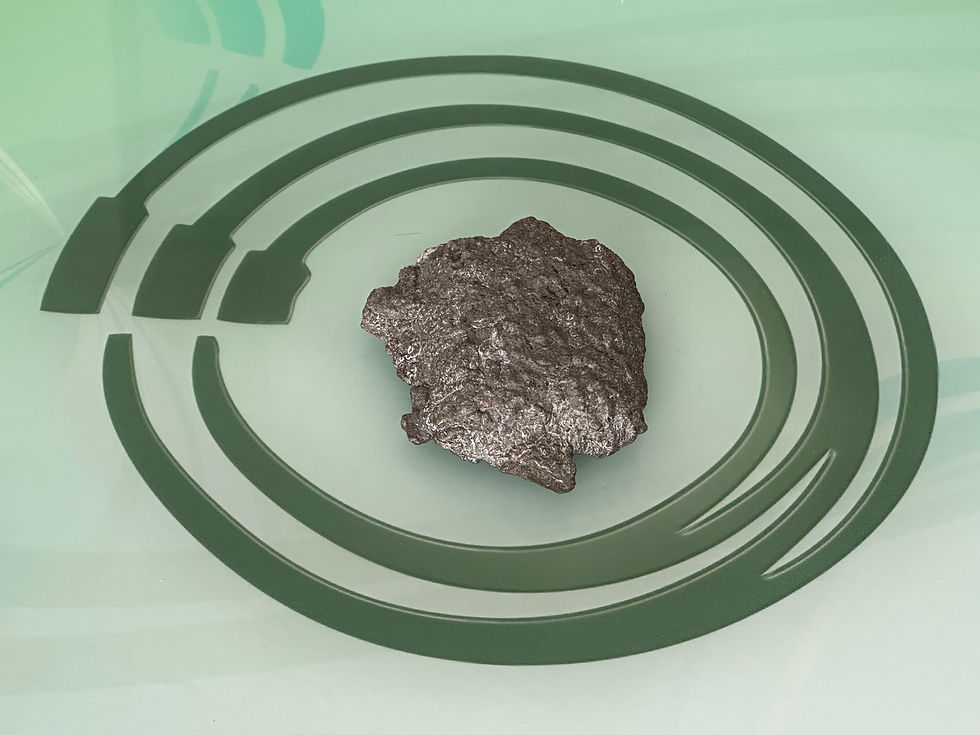

NICKEL ALLOYS

Nickel Alloys, renowned for their exceptional properties, are a versatile group of materials widely utilised in manufacturing across numerous industries. Combining the robustness of Nickel with alloying elements like Magnesium, Boron, Niobium and Vanadium, Nickel Alloys offer superior corrosion resistance, high-temperature strength, and outstanding mechanical properties.

Recognised as a leading Nickel Alloys supplier, Westbrook Resources can assist you with a range of Nickel Alloys.

Our Nickel Alloy Range

Westbrook Resources is a leading Nickel Alloys supplier and distributor to companies in multiple industries across the globe. Click below for more information about each of the Nickel Alloys we supply.

Nickel Alloys in Industry

Nickel Alloys offer exceptional properties for diverse applications. From aerospace components requiring high-strength, corrosion-resistant alloys to chemical processing equipment, Nickel Alloys are an integral part of modern engineering.

Their versatility extends to automotive manufacturing, contributing to lightweight yet robust components. Westbrook Resources is a reliable Nickel Alloys supplier to companies in the UK and beyond, meeting stringent industry requirements for reliability, durability, and innovation.

In addition to being a Nickel Alloys supplier, we also distribute a wide range of ferro alloys, Silicon Alloys, Manganese Alloys and Calcium Alloys. View our full range of products here.

Production of Nickel Alloys

The production of Nickel Alloys begins with extracting Nickel from ore, followed by refining through smelting or electrolysis to achieve high purity Nickel. This is then combined with alloying elements such as Iron, Chromium, Magnesium, Boron or Calcium in precise quantities to enhance its properties.

The alloy is melted in high temperature furnaces (e.g. using an electric arc furnace) and cast into the desired form. These may be further processed through heat treatment such as annealing to improve the mechanical properties or some Nickel Alloys are then forged, rolled or machined into final forms. As a leading Nickel Alloys supplier and nickel alloys distributor, Westbrook have long-established partnerships with highly trusted producers.

Key Properties of Nickel Alloys

Nickel Alloys are valued for their excellent corrosion resistance, especially in harsh environments and their ability to maintain strength at high temperatures. They also offer superior fatigue and wear resistance, making them durable in high-stress applications. With outstanding oxidation resistance and strong mechanical properties, Nickel Alloys are ideal for industries like aerospace, marine, energy, and chemicals. Nickel Alloys are used in the steel industry, often added to steel to enhance its strength, corrosion resistance, and heat resistance. For any business seeking a reliable nickel alloys distributor, Westbrook offers both the technical knowledge and product availability to meet industrial needs.

Global Sourcing and Supply of Nickel Alloys

At Westbrook Resources, we source Nickel Alloys from trusted suppliers worldwide ensuring consistent quality and supply. As a global nickel alloys distributor, our extensive network allows us to meet the demands of the iron and steel industries across multiple regions. Our extensive global network allows us to meet the demands of iron and steel industries across multiple regions. With efficient logistics and supply chain management, we deliver tailored solutions to match your production needs

Our CSR (Corporate Social Responsibility), ESG (Environmental, Social and Governance) and Code of Ethics policies ensure that we conduct our business with the highest standards of integrity, ethics and professionalism in a socially responsible manner. By sourcing raw materials responsibly and adhering to strict environmental regulations, we aim to ensure our operations have a minimal impact on the planet.

The Role of our Nickel Alloys

At Westbrook Resources, we are a Nickel Alloys supplier for use in various industrial applications. Here is a list of what each of our key Nickel Alloys are used for:

Nickel

A versatile base metal offering excellent corrosion resistance and thermal stability. Commonly used in steel production, electroplating, battery production and alloy manufacturing.

Nickel Alloys & Stainless Steel Plate & Bar

These alloys combine Nickel with elements such as Chromium and Iron to enhance corrosion resistance or high temperature resistance facilitating their use in heat treatment applications and in aerospace, marine and chemical processing industries.

Nickel Alloy Weld Wire

Designed for welding applications requiring corrosion resistance and mechanical strength. Ideal for joining dissimilar metals or high-Nickel content alloys in piping, structural and fabrication projects requiring extreme temperature resistance or durability in corrosive conditions.

Nickel Boron

A master alloy used in the production of Nickel-based superalloys and hard-facing applications. It improves hardness and wear resistance in castings and coatings.

Nickel Calcium

Typically used as a deoxidiser and desulphuriser in steelmaking, this alloy refines grain structure and enhances the toughness of the final products.

Nickel Magnesium

Commonly used in ductile iron production, it promotes nodular graphite formation, improving strength, ductility and machinability of cast iron components.

Nickel Niobium

Ideal for producing superalloys with excellent strength and creep resistance at high temperatures. Frequently used in the aerospace, nuclear and energy sectors.

Nickel Vanadium

Used to enhance wear resistance and strength in speciality alloys. It also improves corrosion resistance making it valuable in marine, chemical and aerospace industries. It is also used in the production of precision instruments and semiconductors.

How does Westbrook Resources ensure the quality of its Nickel Alloys?

Our strict quality control framework begins with the sourcing of quality raw materials from trusted and ethical suppliers. Our ISO9001 certified Quality Management System imposes strict quality control procedures to ensure our material meets the standards that we and our customers expect. Our strong reputation in the market is testament to these quality control methodologies and the extremely high standards we set.

Sustainability and Responsible Sourcing of Nickel Alloys

As a responsible nickel alloys supplier, Westbrook Resources is committed to sustainable practices and ethical sourcing. We understand the importance of traceability and environmental stewardship in today’s metals industry. That’s why we work with accredited producers who follow international standards for sustainability and responsible mining.

By prioritising environmentally conscious supply chains and reducing waste through efficient distribution, we help clients meet their sustainability targets without compromising on quality or performance.

Why Choose Westbrook Resources for Nickel Alloys

As a global Nickel Alloys supplier, Westbrook Resources have facilities located in the UK, Europe, Africa and North America. This enables us to supply Nickel Alloys promptly to meet customers’ urgent demands.

Our goal is to be a long-term partner by guaranteeing:

-

Continuity of Supply

-

Consistent Quality

-

Competitive Pricing

-

Effective Delivery Service

-

Quality Service

Westbrook Resources are ISO 9001 compliant, Authorised Economic Operator accredited, hold numerous REACH registrations both in the UK and the EU and have several Turkish KKDIK pre-registrations. We have fiscal representation in several countries to facilitate deliveries directly to your plant.

Contact Us

Westbrook Resources is a trusted Nickel Alloys supplier to a wide range of end-user industries globally. We also supply various other alloys such as calcium, chrome, manganese and noble alloys.

Contact us today to discuss your requirements.

Nickel Alloy FAQs

What is the difference between Nickel master alloys and Nickel-based superalloys?

Nickel master alloys are raw materials used to produce steel or castings (such as Nickel Magnesium and Nickel Niobium), whereas Nickel-based superalloys are castings containing Nickel and other property enhancing metals resulting in high-performance alloys that exhibit outstanding strength, heat resistance and corrosion resistance often used in the aerospace industry (such as Alloy 600 and Alloy 601). As a nickel alloys distributor, Westbrook offers both categories

What are the benefits of Nickel based alloys?

Nickel-based alloys offer a multitude of benefits, including exceptional corrosion resistance, high-temperature strength, and superior mechanical properties. These alloys are highly versatile, making them ideal for a wide range of applications across industries such as aerospace, automotive, and chemical processing. When sourced from a reliable nickel alloys supplier, they ensure longevity and performance, even in the most difficult environments.

Do Nickel Alloys rust?

Nickel Alloys are known for excellent corrosion resistance. They typically do not rust in the same way as ferrous metals. This resistance is due to the formation of a protective oxide layer on the surface of the alloy when exposed to oxygen in the air or moisture.

View our Nickel Alloy range above and contact us today with your enquiries.

How resistant are Nickel Alloys to corrosion?

Nickel Alloys are highly resistant to various forms of corrosion, including:

-

Pitting and crevice corrosion.

-

Stress corrosion cracking.

-

Oxidation and sulphidation.

-

Caustic solutions.

They also maintain and sometimes enhance (depending on which type of Nickel Alloy and the corrosive agent) their corrosion resistance at high temperatures making them ideal for aerospace in addition to chemical processing, marine, and power industries.

Nickel Alloys containing Molybdenum and Chrome also provide resistance to acids, and hydrochloric acid in particular.

How to choose a reliable Nickel Alloys supplier?

When selecting a Nickel Alloys supplier, consider factors such as experience, regulatory compliance (e.g. REACH, CBAM, sanctions etc.), quality accreditations and reputation. Regulatory compliance gives you peace of mind that all applicable laws and regulations have been followed, that your purchasing conditions requiring such compliance have been met and that there can be no potential repercussions from e.g. sanctioned material or REACH avoidance. The quality accreditations and reputation help to ensure the material you receive matches quoted specifications (including chemistry, sizing and packaging) and is delivered on time. Look for a supplier like Westbrook with a proven track record of supplying high-quality metals, ferro alloys and other metal alloys including a wide range of Nickel Alloys to industries worldwide.